Important Safety Information

Important Safety Information

« Click Here

Problem:

“I am pumping the instrument, but chamber pressure is not increasing.”

1. First thing to check is to make sure you are making complete strokes of the piston.

Ensure the instrument is lifted up until it stops. This will ensure that the piston is traveling below the air intake hole at the bottom of the Compression Tube.

2. If there is pressure but consistent leaking –

check the tutorial on leaking.

3. The Compression Tube might have slid out slightly.

Check the Compression Tube to ensure it is properly seated.

You can accomplish this by following these instructions:

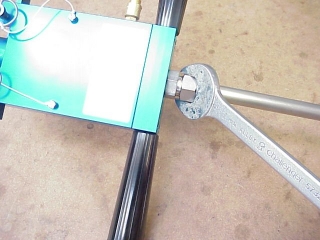

A. Loosen the fitting that holds the Pump-Up tube in place.

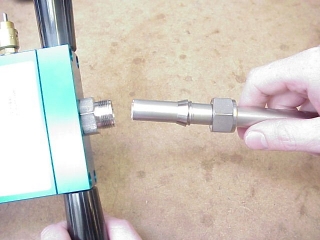

B. Check inside fitting to ensure that O-Ring is in place and that this area is free of excessive grease or debris.

C. Check to ensure that both ferrules are in proper sequence and in good working condition.

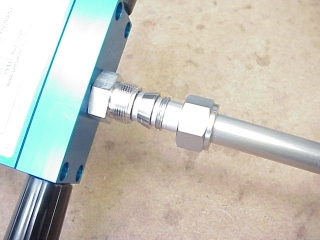

D. Re-insert Compression Tube – ensure it is pushed completely inside of fitting.

E. Tighten nut to finger tight, then tighten 1/8 turn with a wrench. Over-tightening nut swill damage Compression Tube.

4. Check Piston Cup for proper seating, burs or debris.

Piston Cup should be smooth on outside without major scarring or chipping. If damaged, replace as per tutorial.

5) If you are pumping the instrument and it raises up on it’s own when you release it (does not feel like pressure is staying inside chamber).

It is possible the check valve located inside the chamber is plugged and needs to be cleared or replaced. Check the tutorial on leaking for more information about clearing the check valve.